Fuel injection provides a continuously adjustable air/fuel mixture that changes with engine speed, load, throttle position, air temperature, coolant temperature and other operating conditions. This allows EFI to provide an Air/Fuel (A/F) ratio that minimizes emissions while maximizing fuel economy.

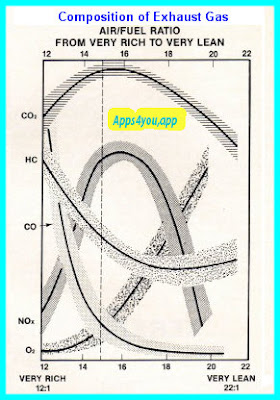

The optimum air/fuel ratio for lowest emissions is 14.7 pounds of air to 1 pound of fuel. This is called the "stoichiometric" ratio (or on European vehicles as Lambda equals one). An A/F ratio of 14.7 to 1 is chemically balanced and results in the most complete combustion with minimal carbon monoxide (CO) and unburned hydrocarbons (HC). Oxides of nitrogen (NOx) can still be relatively high depending on combustion temperatures, but at an A/F ratio of 14.7 to 1 a three-way catalytic converter will break down most of the NOx in the exhaust. The end result is almost zero HC and CO coming out of the tailpipe, and very little NOx.

BASIC EFI SYSTEMS There are two basic types of EFI systems: mass airflow and speed/density. With mass airflow systems, some type of airflow sensor is used to measure the volume of air entering the engine. On most late model vehicles, a hot wire Mass AirFlow (MAF) sensor is used. A MAF sensor reads airflow by varying the current needed to heat a wire that is cooled by air flowing past the wire. On many older vehicles (1990s vintage), a spring-loaded vane airflow sensor (VAF) was used to sense airflow. Toyota has also used a "vortex" airflow sensor on some models that detected turbulence in the airflow to indicate flow. The airflow sensor is located in the tubing between the air cleaner housing and throttle. The MAF sensor's reading is combined with other sensor inputs such as engine RPM, throttle position, engine load (via a Manifold Absolute Pressure sensor) and other information to calculate what the optimum A/F ratio should be for that particular moment.

Speed/density EFI systems do not have an airflow sensor. Airflow is estimated using engine RPM, inlet air temperature, throttle position and engine load (via the MAP sensor). A speed/density system is not as sophisticated as a mass airflow system, but it is less expensive for the auto maker because it requires no MAF sensor. A speed/density EFI system is also less sensitive to small air leaks that may occur in the tubing between the air cleaner and throttle, or in the intake manifold or vacuum hoses that connect to the manifold. Air leaks can throw off a mass airflow EFI system and cause it to run leaner than normal because "unmetered" air that sneaks into the engine on the down wind side of the airflow sensor is not factored into the A/F calculations. FEEDBACK FUEL CONTROL Electronic EFI systems also use one or more Oxygen (O2) sensors or Air/Fuel (A/F) Sensors to constantly fine tune the A/F mixture. Both types of sensors monitor unburned oxygen in the exhaust. The computer uses this information to determine if the A/F mixture is running rich (too much fuel, not enough air) or lean (too much air, not enough fuel). This creates a feedback loop that allows the EFI system to fine tune the A/F mixture beyond what the other sensor inputs are telling the computer.

The upstream oxygen sensor tells the PCM if the engine is running rich or lean so the PCM can readjust the A/F ratio. The downstream O2 sensor is used primarily to monitor catalyst efficiency. On some applications, input from the downstream O2 sensor is also used for additional long term fuel trim adjustments. WHY THE A/F RATIO IS ALWAYS CHANGING The A/F ratio is not constant but is constantly readjusting according to changing operating conditions. For example, a significantly richer A/F ratio is required following a cold start so the engine will idle smoothly without stalling. A richer mixture is also needed when the engine is under load for more power, and when the throttle suddenly snaps open to prevent hesitation. Sometimes the A/F ratio can be made leaner than usual to improve fuel economy, such as when the vehicle is cruising under light load and throttle. The fuel mixture can also be leaned out or cut off entirely during deceleration to conserve additional fuel. It all depends on the operating strategies programmed into the computer. Reprogramming the computer is sometimes necessary to correct an emissions or driveability problem.

HOW THE AIR/FUEL RATIO IS CHANGED

The A/F ratio is adjusted by varying the pulse duration, duty-cycle or on-time of the fuel injectors. Increasing the on time of each injector pulse sprays more fuel into the engine and richens the A/F mixture. Decreasing the on time of each injector pulse leans the A/F mixture and reduces the volume of fuel sprayed into the engine. The speed of the computer determines how quickly such changes can be made. Many late model EFI systems are so fast they can readjust the A/F mixture between individual cylinder firings!

Basically, the engine computer does the opposite of what the oxygen sensors are telling it. When the O2 sensors read lean, the computer richens the A/F ratio and increases injector duration to richen the fuel mixture. When the O2 sensors read rich, the computer shorten the injector pulses to lean the fuel mixture.

Fuel trim values can be read on a scan tool.

The STFT readings shown here are abnormally high

because the engine is off. As soon as the engine starts,

the actual values will start to display.

The STFT readings shown here are abnormally high

because the engine is off. As soon as the engine starts,

the actual values will start to display.

MONITORING FUEL TRIM

The computer monitors the constantly changing A/F ratio by tracking "short term fuel trim" (STFT) and "long term fuel trim" (LTFT). You can view the fuel trim values on a scan tool to get a good idea of what kind of corrections are being made, and whether or not these corrections indicate a possible problem.

STFT is what's happening right now. STFT is constantly jumping around as the computer adjusts and readjusts the A/F ratio.

LTFT is how the fuel mixture is trending over time, and is the best indicator to tell you if the engine is running too rich or too lean and is possibly experiencing an emissions problem.

POSITIVE (+) fuel trim numbers mean the EFI system is adding fuel to compensate for a LEAN A/F mixture.

NEGATIVE (-) fuel trim numbers mean the EFI system is subtracting fuel to compensate for a RICH A/F mixture.

The changes in fuel trim are based on what the oxygen sensors are telling the engine computer. Consequently, fuel trim values and adjustments are only as accurate as the oxygen sensor inputs.

Any number of things can create inaccurate oxygen sensor readings. A misfiring spark plug, a leaky exhaust valve, or an air leak in the exhaust manifold gasket can allow false air into the exhaust. This will cause the O2 sensor to read leaner than it should, which in turn will cause the computer to richen the fuel mixture unnecessarily and increase the fuel trim numbers. This can hurt both fuel economy and emissions.

Conversely, if an old oxygen sensor is sluggish, contaminated, unresponsive or dead, it may underreport exhaust oxygen levels. This will mislead the computer into thinking the mixture is richer than it really is. The computer will lean out the mixture unnecessarily, causing the fuel trim numbers to go negative. An overly lean A/F mixture will increase NOx emissions, increase the risk of detonation (spark knock), and increase the risk of lean misfire -- which will cause a drop in performance and fuel economy, as well as a big jump in hydrocarbon emissions.

Ideally, STFT and LTFT should both be within a few percentage points of zero when the engine is idling or being held at a steady RPM and load. Good LTFT readings should be as close to zero as possible, though they often range from 5 to 8 percent depending on the condition of the engine. If LTFT numbers are more than 10, it usually indicates a problem that needs to be diagnosed. LTFT values that go as high as 20 or higher will usually set a P0171 or P0174 lean code and turn on the Check Engine light.

High positive LTFT fuel trim numbers due to a lean A/F mixture may be the result of dirty fuel injectors, a dirty mass airflow sensor, vacuum leaks at the intake manifold or in vacuum hoses, a weak fuel pump, or a faulty fuel pressure regulator that cannot maintain adequate pressure to the injectors.

Electronics cleaner can be used to clean a dirty MAF sensor, while fuel cleaner or an off-car injector cleaning machine can be used to clean dirty injectors. Vacuum leaks can often be found by lightly pressurizing the intake manifold (no more than 3 or 4 PSI) and spraying soapy water on suspected leak points. Bubbles anywhere indicate a leak. Mineral oil vapor can also be fed into the intake manifold under light pressure using a smoke machine to search for small leaks.

Excessive negative LTFT fuel trim numbers caused by a rich A/F mixture may be the result of oxygen sensors that need to be replaced, false air getting into the exhaust, compression leaks, ignition misfire (check the spark plugs and coils), one or more leaky fuel injectors, or excessive fuel pressure due to a faulty fuel pressure regulator.

Aucun commentaire:

Enregistrer un commentaire